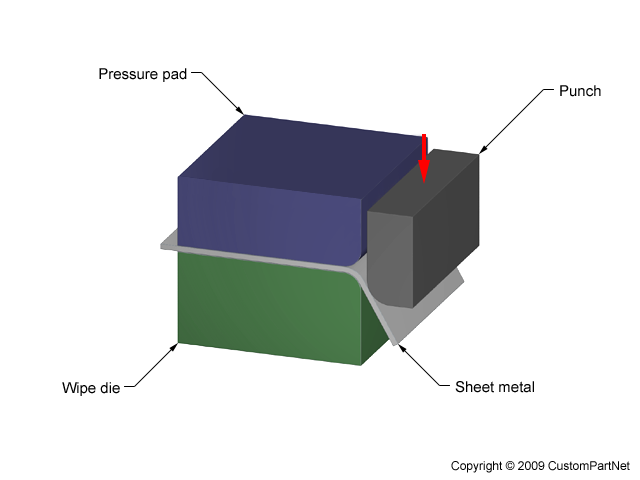

A bending operation causes deformation along one axis but a sequence of several different operations can be performed to create a complex part.

How much does one bend in sheet metal cost.

Material cost is one of the most significant drivers of part costs.

Design 45 welding 33 processes 22 materials 21 sheet metal 18 applications 11 aluminum 9 cost 9 steel 6 finishing 4 stainless steel 4 value analysis value.

See how to lower your sheet metal cost.

When specialty pieces of sheet metal are required for a project homeowners may pay stamping fees that add an average of 2 per square foot to the cost of sheet metal.

Cells on the right will output the desired values.

For pricing and availability.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

Hillman 24 in x 36 in steel solid sheet metal.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.

Fixing structural damage costs an average of 85 per hour in labor plus the cost of replacement materials.

Ultimate tensile strength psi.

Die edge radius in.

Bending is a metal forming process in which a force is applied to a piece of sheet metal causing it to bend at an angle and form the desired shape.

When making a bend in sheet.

For pricing and availability.

However because sheet metal parts are made from a single flat sheet there are additional design considerations compared to other machining processes.

Sheet metal bend cost tbuelna aerospace 23 aug 14 23 32 as others noted if this is a brake forming operation you need performed by a us vendor then change the inside bend radius to an inch increment like 75 or 19mm which is only 037 smaller than 20mm.

Please contact one of our skilled fabricators.

Fabricate sheet metal calculator let s calculate cost data for you.

Can you bend sheet metal too much.

Choose the appropriate material.

Hillman 12 in x 24 in copper decorative sheet metal.

Join our monthly email list.

Punch edge radius in.

To help you save time and money here are 5 tips you can use on your next project.